Designing service

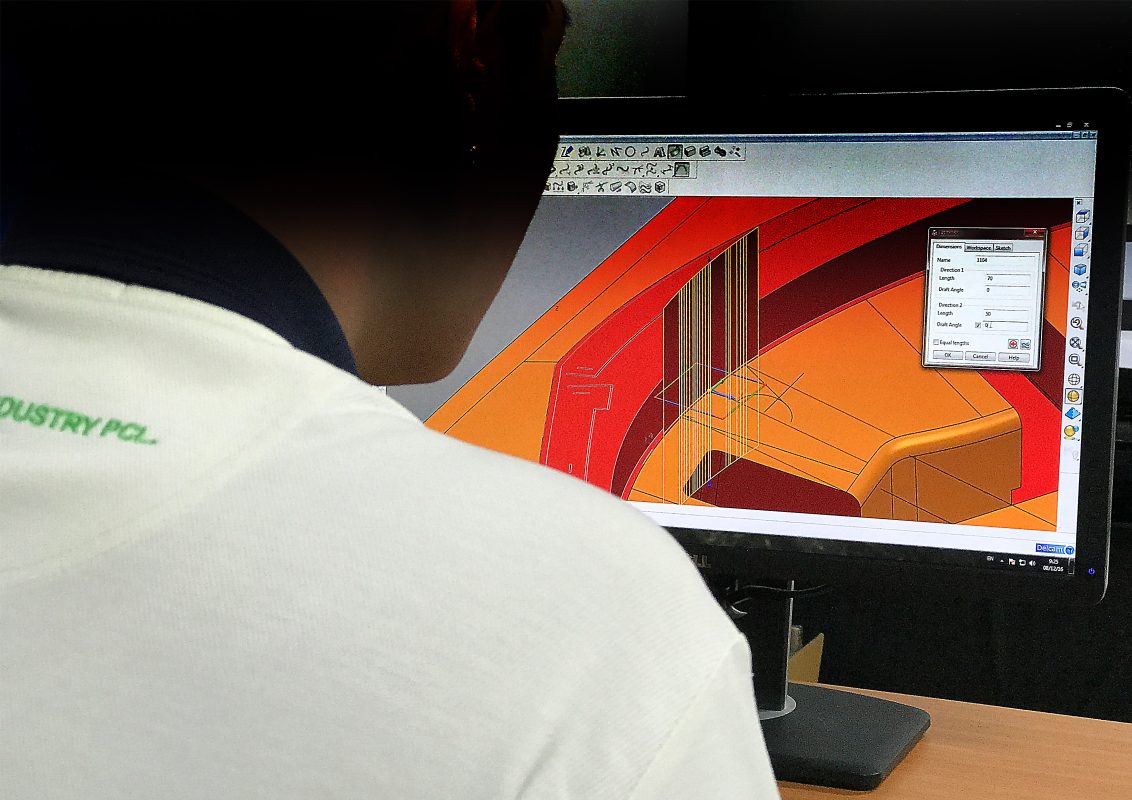

Our company can design an outstanding product design for auto parts. We utilize CAD design software for our product as it provides better quality, rapid and accurate result. We also have a high level CAD styling skills. With this software, It enables us to explore design ideas in both 2D and 3D, easily modify designs, visualize concepts through renderings, simulate how a design operates in the real world, generate documentation, share designs for feedback. Additonally, we help customers throughout the process from product and idea design to creating mockup models. We build upstream style concepts while taking production requirements into consideration. We will collaborate with our customers until we reach customer need at any level of the design process.

DESIGNING PROCESS

1. DISCOVER

We will meet with our customers and discuss with them about their requirements and expectations, including conducting a research to better understand our customers. We then submit a proposal that matches with customer budget.

2. Concept design

We will build various conceptual models that aligns with customer requirements, preferences and market trend in that specific time, letting our customers to see many creative ideas. The specialty of this process is that our customers can be a part of the product design by adding their ideas in their product design. The program that will be used in this styling process includes Photoshop, Adobe Illustrator, and Autodesk Sketchbook.

3. product engineering

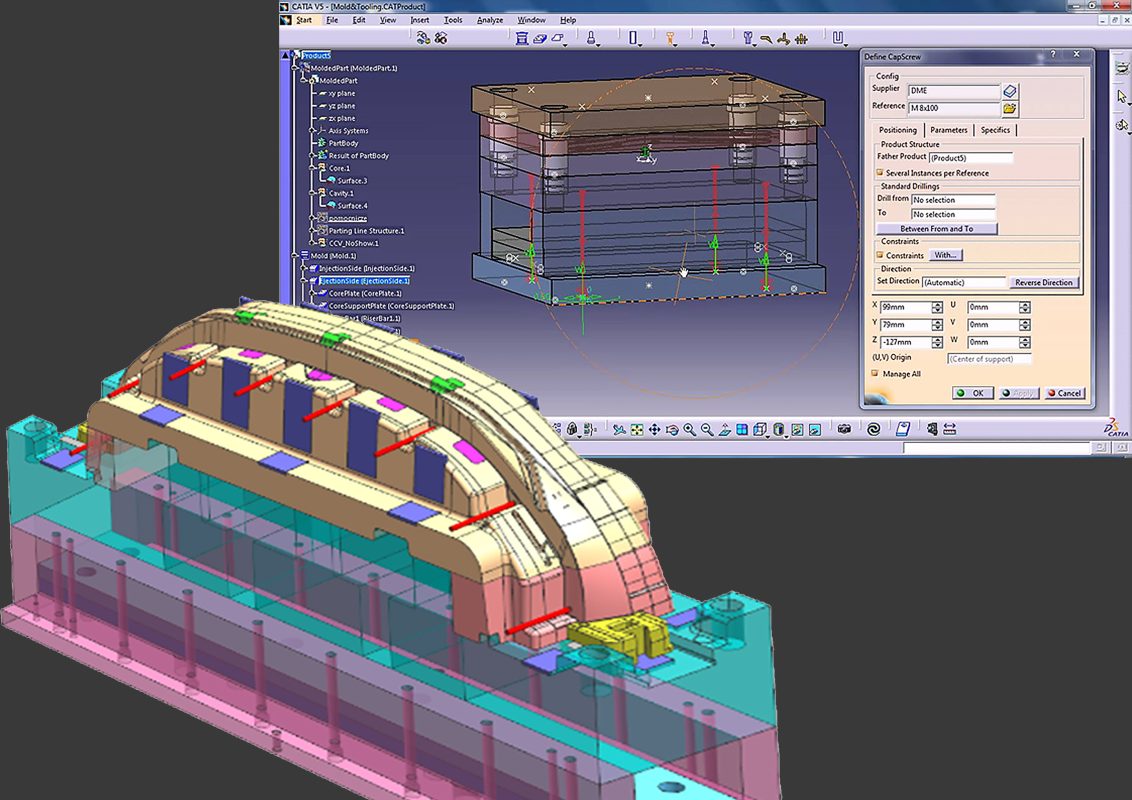

We use the most recent CAD software tool and a highly-skilled engineering team to create an engineering solutions and to bring the product concept to reality, by analyzing the design of the product detail in 3D. A clear and concise image of the completed product will be rendered by CAD software, PLM software, Catia Software, Autodesk Powershape. With this software, it enables us to check our work before constructing the actual work.

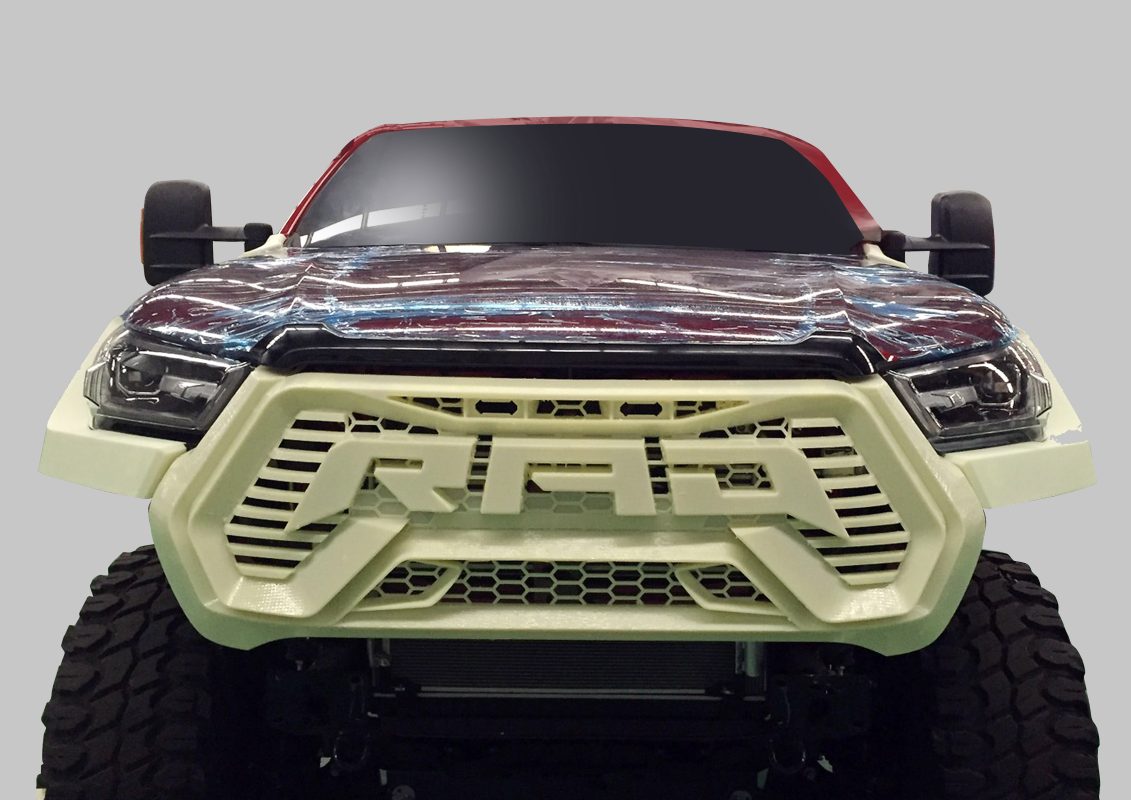

4. prototype design

After getting the design from product engineering process, we will make a physical prototype by printing 3D prototype, to ensure that this design will fulfill all customer requirements and preferences, including making this product design becomes like a real product as much as we can. Furthermore, creating a prototype helps us to collect data, allows us to solve any issues, examines what works and what doesn’t, and make any major modifications before final production.

5. design for manufacture

In this stage, customers are satisfied with the product design, and the product design is ready to proceed in next process, which is mold design. Moreover, as we are based in Asia, design for manufacturing is an important component of our skill set, enabling us to create cost-effective products that maximize profitability.

our previous work

MORE PREVIOUS WORKS FROM US...

BEFORE

AFTER (SPORT DESIGN)

BEFORE

AFTER (SPORT DESIGN)

join our newsletter

STAY INFORMED WITH US!